In the evolving world of electric vehicles (EVs), motor technology plays a pivotal role in enhancing performance, energy efficiency, and overall driving experience. As EVs gain popularity, the debate between coreless DC motors and traditional motors, such as brushed DC motors and permanent magnet synchronous motors (PMSMs), becomes increasingly important.

What Are Coreless DC Motors?

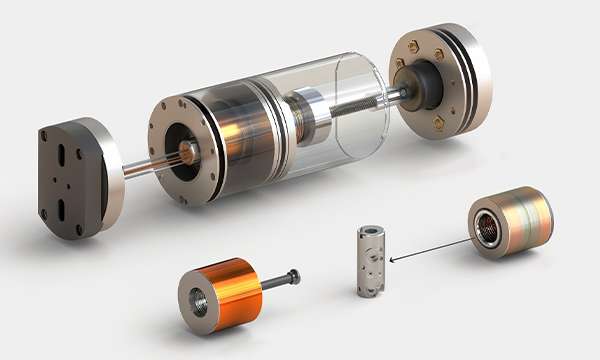

Coreless DC motors, including the coreless BLDC motor, are a type of brushless DC motor. Unlike traditional DC motors that rely on an iron core to create a magnetic field, coreless DC motors utilize a rotor made from a lightweight material that eliminates the need for an iron core. This results in a more compact and efficient design, with less heat generation and higher torque output in a smaller package.

Traditional Motors: Brushed DC and PMSM

Traditional DC motors, like brushed DC motors, use brushes to deliver electrical current to the motor windings, creating a magnetic field that interacts with the rotor to produce motion. While they are simple and cost-effective, brushed DC motors are prone to wear and tear due to the friction between brushes and the commutator, leading to reduced lifespan and maintenance needs.

Permanent Magnet Synchronous Motors (PMSMs), on the other hand, use permanent magnets to create a magnetic field and are commonly found in electric vehicles due to their efficiency and performance. These motors offer high torque and power density, making them ideal for larger, more powerful EVs. However, they require sophisticated control systems and can be more expensive to manufacture than traditional brushed motors.

Performance Comparison

Compared to conventional brushed DC motors, coreless DC motors provide a number of performance advantages. For one, the absence of an iron core reduces cogging, resulting in smoother and quieter operation. This is particularly beneficial for EVs, where noise reduction is often a priority for consumer satisfaction.

Coreless DC motor also exhibits better efficiency, as they are less prone to energy losses caused by friction and resistance. Their lightweight rotor design reduces inertia, leading to quicker acceleration and higher torque-to-weight ratios. This allows EVs to achieve better performance with less power consumption, which is crucial for extending range and reducing battery drain.

In contrast, while traditional PMSMs are highly efficient, they tend to be heavier and larger, which can affect the overall design of the vehicle. Additionally, their reliance on rare-earth magnets makes them more expensive to produce, driving up the cost of the vehicle.

Durability and Maintenance

Since they do not rely on brushes for commutation, they experience less wear and tear, resulting in a longer operational lifespan. This feature reduces the maintenance burden on EV owners and enhances the overall reliability of the vehicle.

Because the brushes and commutator make mechanical contact, traditional brushed DC motors need to have their worn-out brushes replaced on a regular basis. While PMSMs are more durable than brushed DC motors, they still require more complex cooling and control systems to operate optimally.

Efficiency and Energy Use

Efficiency is one of the most critical factors in the design of EV motors, and coreless DC motors excel in this area. Better energy conservation, longer battery life, and enhanced overall performance are all results of their great efficiency. By reducing energy losses, these motors help EVs achieve higher mileage per charge, making them a more attractive option for consumers looking to minimize their environmental footprint and operating costs.

Traditional motors, such as brushed DC motors, are generally less efficient due to energy losses from friction and resistance. Although PMSMs offer high efficiency, they come with higher manufacturing costs and more complex control systems, which can offset some of their advantages.

Conclusion: Which is Better for Electric Vehicles?

The choice between coreless DC motors and traditional motors for electric vehicles depends on the specific needs and goals of the manufacturer. Coreless DC motors offer superior performance, energy efficiency, and durability, making them an excellent choice for compact, high-performance EVs. Their light weight, smooth operation, and low maintenance requirements make them particularly well-suited for premium electric vehicles and applications where efficiency and precision are paramount.

Traditional motors, particularly PMSMs, remain a strong contender for larger, more powerful EVs that prioritize high torque and long-range capabilities. Ultimately, as the EV industry continues to evolve, coreless DC motors are likely to play an increasingly prominent role in shaping the future of electric mobility. Coreless DC motor manufacturers continue to innovate, pushing the boundaries of what these motors can do, ensuring that electric vehicles become more efficient, affordable, and sustainable in the years to come.